LEMONT, Ill. – Sometimes, all it takes is an extremely small amount of material to make a big difference.

Scientists at the U.S. Department of Energy's Argonne National Laboratory have recently discovered that they could substitute one-atom-thick graphene layers for either solid- or oil-based lubricants on sliding steel surfaces, enabling a dramatic reduction in the amount of wear and friction.

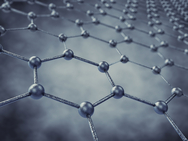

Graphite is a commonly used solid lubricant. However, it works best in moist air and does not protect the surface from tribo-corrosion. New studies led by Argonne materials scientists Anirudha Sumant and Ali Erdemir show that single sheets of graphite, called graphene, work equally well in humid and dry environments. Furthermore, the graphene is able to drastically reduce the wear rate and the coefficient of friction (COF) of steel. The marked reductions in friction and wear are attributed to the low shear and highly protective nature of graphene, which also prevents oxidation (tribo-corrosion) of the steel surfaces when present at sliding contact interfaces.

Argonne National Laboratory:

Graphene layers dramatically reduce wear and friction on sliding steel surfaces

Comments