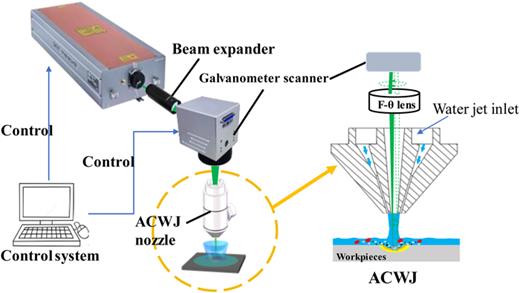

Schematic of annulus-conical water jet-assisted laser machining. Fig 1

Topics: Applied Physics, Composite Materials, Fluid Mechanics, Lasers, Materials Science, Nanoengineering

Abstract

When processing SiC/SiC composites using nanosecond-pulsed lasers, thermal effects such as molten deposition and heat-affected zones (HAZs) will occur. In this study, an annulus-conical water jet (ACWJ) was introduced to assist nanosecond laser machining of SiC/SiC composites, aiming to suppress thermal damage. A comparative investigation between laser processing in air and under ACWJ assistance was conducted. The results demonstrated that ACWJ assistance effectively eliminated molten material deposition and HAZs, significantly improving surface quality. However, despite a short beam path in the water (approximately 2.5–3 mm), turbulence in the water stream during ACWJ processing caused beam divergence and focus drift, leading to a substantial reduction in laser energy density on the target surface, and thus a lower material removal efficiency compared to laser machining in air. Moreover, the beam focal position drifted within the turbulent water stream, resulting in broader and shallower machined features. The material removal rate during ACWJ-assisted laser processing was only approximately 3%–10% of that achieved in air. In groove ablation, achieving the same depth as that in air-based processing required a significantly larger number of scan passes under ACWJ conditions. In hole machining, the resulting hole diameters were approximately 240% greater than those achieved in air.

Processing of SiC/SiC composite using an annulus-conical water jet-assisted nanosecond-pulsed laser, Zhuang Liu, Weicheng Xu, Chenhao Li, Tianrui Liu, Changshui Gao, Journal of Applied Physics

Comments